Is Ousikai WPC Flooring the Durable Choice for Modern Homes

People today want flooring that can handle real life without turning into a constant headache. Traditional options often show their weaknesses pretty quickly—some swell up when things get humid, others crack under heavy use, and plenty feel icy or noisy underfoot. WPC Vinyl Flooring has stepped up as a smart middle-ground solution. It mixes processed wood fibers with strong polymers to build a surface that looks convincingly natural while dealing much better with spills, humidity swings, and everyday traffic. The combination gives homeowners and installers something reliable that doesn’t demand ideal conditions to stay looking good.

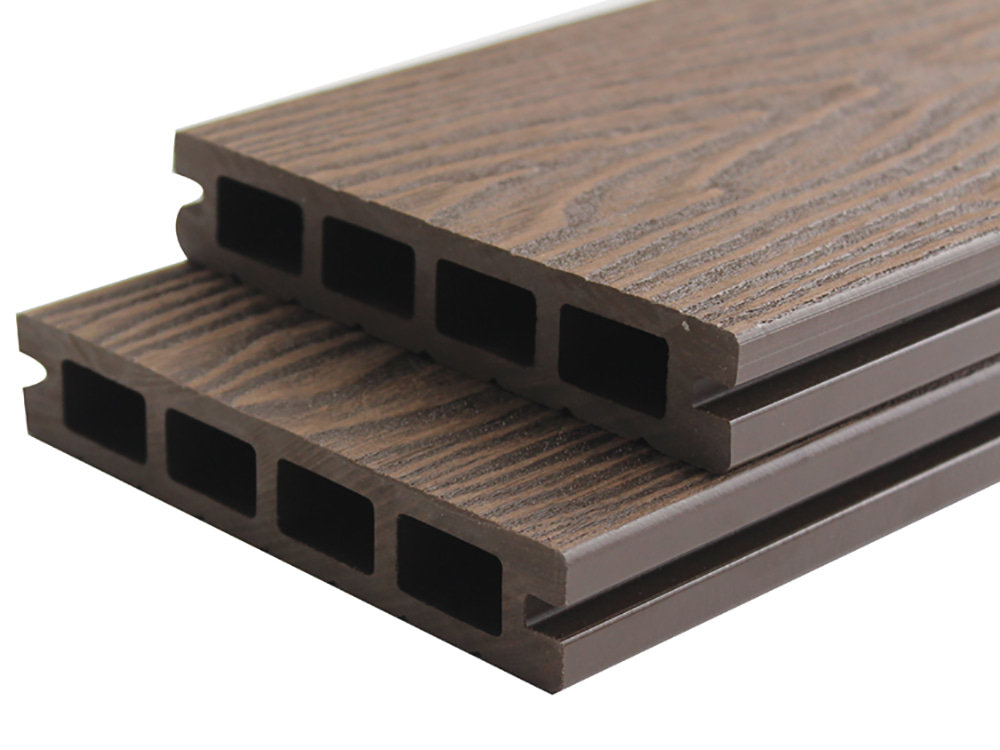

The core of this kind of flooring is where the real work happens. Fine wood fibers get blended thoroughly with binding polymers, creating a dense, stable platform underneath. This base layer resists the kind of expansion and contraction that ruins many conventional floors during seasonal weather changes. Pressure from furniture legs or people walking across spreads out more evenly instead of concentrating in weak spots that could cause to dents or cracks. The result stays firm enough to feel solid and trustworthy but still has just enough built-in flex to avoid the completely unforgiving hardness of pure tile or stone.

Extra thickness makes a noticeable difference in how the floor performs day to day. Deeper construction soaks up impacts from dropped items more effectively and cuts down on the echo of footsteps, helping rooms stay quieter without needing separate soundproofing layers in many situations. Installers often mention how this added depth creates a more premium, grounded feeling underfoot compared to very thin sheets that can sometimes feel cheap or flimsy.

Putting it down tends to stay pretty straightforward for many people. The planks connect along their edges with a simple mechanical click system—no glue to spread, no nails to hammer, and no waiting around for anything to dry. A basic utility knife, some spacers, and a tapping block usually cover all the cutting and alignment work. Once the subfloor has been checked and leveled where needed, large open areas can come together fairly quickly without requiring advanced skills or extra crew.

Layers That Define Performance

Each part of the build contributes something specific that makes the whole system work reliably. The bottom section serves as the main structural backbone. Processed fibers and polymers combine into a uniform, heavy-duty core that fights against bending, swelling, or shrinking when indoor humidity rises and falls over time.

Right above that sits the decorative surface. Modern printing technology reproduces fine details of wood grain, stone texture, and other natural looks with impressive realism. These visuals stay protected because multiple clear layers sit on top, blocking everyday scuffs from shoes, fading from bright windows, and minor accidents.

The very top gets a tough, see-through finish engineered to take serious punishment. It stops liquids from soaking in, keeps colors stable even under direct sunlight, and makes typical household spills wipe away easily with just a damp cloth and mild cleaner—no fancy products required.

Key Structural Components Compared

The different levels team up to deliver balanced, long-lasting results.

| Layer Position | Primary Material Composition | Main Function | Contribution to Overall Durability |

|---|---|---|---|

| Base Support | Blended wood fibers and polymers | Provides structural rigidity and stability | Prevents warping, swelling, or shrinking due to humidity |

| Intermediate Bonding | Adhesive-free composite matrix | Distributes weight evenly | Boosts impact resistance and lowers noise transfer |

| Visual Design Layer | Printed high-resolution patterns | Offers aesthetic variety | Keeps the look appealing for many years |

| Protective Surface | Transparent durable coating | Shields from scratches, stains, moisture | Makes cleaning easy and helps retain original appearance |

Practical Advantages in Everyday Use

What really pulls people toward this kind of flooring is the way it deals with water day in and day out. Drinks knocked over, pet mishaps, grease popping out of pans, or even a slow drip from a pipe—none of it soaks in or wrecks the structure underneath. The surface stays flat and firm even after repeated exposure to damp air or standing puddles. That kind of reliability makes a noticeable difference in busy kitchens where something spills almost every day, in bathrooms that stay steamy after showers, in laundry rooms with occasional overflows, or in basements that sometimes feel the effects of groundwater. Keeping the floor clean doesn' t turn into a big production either. A quick pass with a broom or vacuum picks up dust and crumbs, and a lightly damp mop with plain cleaner wipes away marks without leaving streaks or dull patches behind.

Cost-wise, it usually sits in a comfortable middle ground. The way these floors get made has improved over time, so you end up paying less than you might expect for something that holds up this well and looks decent. Folks who are fixing up a place often pick this route because it delivers solid results without eating up the whole budget set aside for the project.

The looks available run the gamut. You can go with quiet, low-key patterns that have soft wood lines barely showing, or step up to stronger designs that copy weathered barn boards, hardwoods, or even slate and travertine stone. Having that spread of choices helps the floor fit right in with whatever furniture, paint, or rugs are already there—or it lets you start fresh without the new surface clashing against everything else in the room.

The feel when you walk or stand on it comes mostly from how the inner layers are put together. That mix of ingredients gives a bit of give under pressure, so it doesn' t pound back against your feet and knees the way concrete, ceramic, or even some hardwoods do after hours on your feet. The difference shows up in places where you spend a lot of time upright—cooking dinner, folding laundry, or just moving through the house.

Things to Think About During Installation and Setup

Getting a good outcome starts with looking closely at whatever surface is already down below. High ridges, sunken spots, small cracks, or bumpy areas all need attention because they can push up through the new planks and show as visible waves or unevenness later on. Most of those problems clear up with a bag of self-leveling compound spread out or a quick run with sandpaper or a floor sander—no major demo work required in typical cases.

Giving the material time to sit in the room before you start cutting and clicking pieces together makes a real difference. A day or two lets everything settle into the local air temperature and moisture level. When that step gets skipped, planks sometimes shift a tiny bit or pull apart at the seams once they' ve had time to adjust on their own. Waiting a short while avoids those small frustrations that pop up weeks after the job is done.

The tools needed stay basic and easy to find. A tape measure, a square for straight lines, a sharp utility knife, plastic spacers to keep even gaps, a tapping block to seat the connections, and a pull bar for the last pieces near the wall usually cover everything. Spending a few extra minutes measuring carefully around door frames, heat vents, and inside corners keeps the cuts clean and the finished edges looking tight. Leaving a slim gap—about the thickness of a coin—along the walls and around cabinets gives the floor space to expand and contract naturally when the seasons change, without pressing hard ag

Maintenance Routines for Longevity

Daily habits make the biggest difference in keeping the surface looking new. Regular sweeping or vacuuming with a hard-floor attachment removes dust, sand, pet hair, and grit before those particles can grind away at the top layer over months and years.

When something spills, addressing it right away helps prevent staining. Blotting instead of rubbing, then using a mild cleaner, keeps the protective finish intact without causing haze, streaks, or dull spots.

Every few months, a quick walk-around to check seams and edges catches any loosening early. Pressing pieces back into place usually restores a smooth, even feel across the room and stops dirt from working its way down into joints where it' s harder to clean out.

Environmental Adaptability in Different Spaces

This type of flooring works comfortably in many different parts of a home or business. Kitchens shrug off cooking splatters and quick wipe-downs keep them presentable after meals. Bathrooms handle steam and occasional water near tubs or sinks without losing shape or integrity.

Main living areas stay cozy with a warmer touch compared to cold tile or bare concrete. Entryways catch tracked-in dirt and moisture from shoes without showing rapid wear. Bedrooms benefit from quieter footsteps and a softer feel during rest periods.

Even transitional zones like covered patios or sunrooms sometimes use it successfully when direct rain and harsh weather remain blocked. Limiting exposure to harsh outdoor conditions helps everything last longer in those border areas.

Comparison to Traditional Flooring Types

Older materials each come with their own trade-offs. Solid hardwood expands and contracts noticeably with humidity changes, often needing careful indoor climate control to avoid gaps or buckling. Ceramic and porcelain tiles resist scratches well but stay cold underfoot, echo footsteps loudly, and require regular grout cleaning and sealing.

Engineered wood products improve on some stability issues compared to solid planks but still hesitate in consistently wet environments in many cases. Large sheet vinyl creates seamless expanses but becomes tricky and expensive if only one damaged section needs replacing.

This composite approach pulls together several strong advantages—straightforward click installation, reliable water resistance, and believable natural-looking designs. That practical balance is why more people choose it for both whole-house remodels and targeted room updates.

Long-Term Value and Resilience Factors

Durability grows from thoughtful engineering across every layer. The core pushes back against dents from heavy objects and scuffs from regular foot traffic. Light temporary impressions often recover naturally thanks to the flexible elements inside the construction.

Sunlight rarely causes dramatic color shifts when the top protective coating does its job properly. Steady, consistent tones help the floor keep matching the rest of the interior for years without needing premature replacement.

If a future redesign calls for changes, disassembly stays manageable. The locking system allows careful removal of planks with minimal destruction, and saved pieces can patch small damaged areas or fill closets and pantries.

Trends in Flooring Material Development

Manufacturers keep refining existing formulas while experimenting with more sustainable inputs. Recycled and renewable content appears more often without sacrificing performance or appearance. Production methods focus on cutting waste and lowering energy use wherever possible.

Advancements in surface treatments aim for better resistance to scratches, scuffs, and everyday wear. Subtle embossing and texturing add a more authentic tactile experience that pairs well with the high-definition printed visuals underneath.

Shoppers continue asking for faster, cleaner installation processes and easier ongoing maintenance. Those preferences keep pushing the industry to improve both the product and the user experience over time.

Practical Insights for Selecting Composite Flooring

Every flooring decision comes down to figuring out how the room actually gets used day to day, what kind of weather patterns the area sees, how much money is realistically available, and what visual direction the space is heading toward. Surfaces that manage to balance several of these elements at once tend to work out better across a wider range of homes and situations.

Composite-core products hold steady in places where moisture shows up often or traffic stays heavy, all while keeping a believable natural appearance that blends into contemporary interiors. The way the different layers interact gives solid everyday performance without ignoring the decorative side of things.

Developments in materials continue happening at a steady pace, so the choices keep aligning more closely with current lifestyles and expectations. Practical performance combined with straightforward handling explains why these options show up so frequently in both new builds and older-home updates.

Ousikai operates as a focused factory specializing in high-quality composite flooring production. Long experience shapes every production run, with careful oversight at each stage—from precise blending of core components, through secure layer integration, to the final surface treatments. The production crew prioritizes delivering uniform strength and dependable visual results that satisfy requirements coming from different regions and applications. Regular upgrades to machinery along with thorough quality verification processes support consistently high standards that contractors and homeowners rely on year after year. Ousikai stays dedicated to pushing composite flooring capabilities forward while maintaining efficient, trustworthy manufacturing for continuing demand.

English

English 中文简体

中文简体 Español

Español