What is WPC Flooring?

What is WPC Flooring?

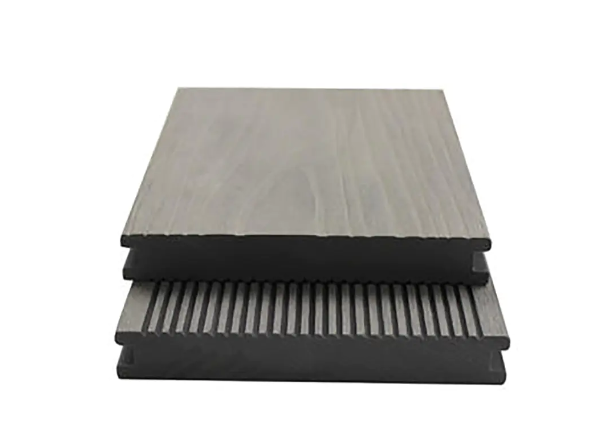

WPC Flooring, or Wood Plastic Composite Flooring, is a type of engineered flooring that combines the natural aesthetic of wood with the durability and performance of plastic. It is made from a blend of wood fibers (or sawdust) and plastic (usually PVC or other polymers), which are compressed together to form a sturdy, durable, and moisture-resistant floor. WPC flooring is designed to provide an alternative to traditional hardwood flooring while offering enhanced benefits such as increased water resistance, ease of maintenance, and installation flexibility.

The unique combination of wood and plastic in WPC flooring gives it the best of both worlds— the aesthetic appeal of wood with the practicality of synthetic materials. This type of flooring is becoming increasingly popular for both residential and commercial spaces due to its superior performance and versatile design options.

How is WPC Flooring Made?

The process of creating WPC flooring involves a mix of wood fibers, plastic resins, and various additives. The components are blended and then extruded into planks or tiles, which are compressed to achieve the desired thickness and strength. The material is then layered with a high-definition printed surface that mimics the look of real wood or stone. The top layer is typically coated with a wear layer that adds extra protection against scratches and fading.

The key components of WPC flooring include:

Wood fibers or sawdust: Derived from recycled wood, these fibers are responsible for the floor’s natural wood-like appearance.

Plastic resins: Typically made from polyvinyl chloride (PVC), these plastics provide the strength, moisture resistance, and flexibility that make WPC floors ideal for wet areas.

Additives: Various chemical agents are used to enhance properties like UV protection, flame resistance, and anti-bacterial effects.

Advantages of WPC Flooring Over Other Flooring Options

1. Superior Water Resistance

One of the most significant advantages of WPC flooring is its exceptional water resistance. Unlike traditional hardwood flooring, which can warp, swell, or even mold when exposed to moisture, WPC flooring is designed to handle wet conditions with ease. The plastic core and protective layers prevent water from seeping into the material, making it a fantastic option for high-moisture areas like kitchens, bathrooms, basements, and laundry rooms.

Comparison with other flooring types:

Hardwood: Prone to water damage, expansion, and contraction in humid environments.

Laminate: While laminate can handle some moisture, it is not as water-resistant as WPC and can swell or warp when exposed to excess water.

Vinyl: Vinyl is water-resistant, but it lacks the natural feel and appearance of wood, unlike WPC.

WPC flooring, however, maintains its structural integrity and appearance even in the face of moisture, making it ideal for areas where water exposure is common.

2. Enhanced Durability

WPC flooring is known for its increased durability compared to other traditional flooring options. The combination of wood fibers and plastic makes the material highly resistant to scratches, dents, and general wear and tear. The protective wear layer adds an extra shield against damage from heavy foot traffic, pets, and furniture.

Comparison with other flooring types:

Hardwood: While hardwood floors are durable, they can be scratched or dented by heavy objects, pets, or high heels.

Laminate: Laminate is relatively durable but more prone to scratches and damage compared to WPC flooring.

Vinyl: Vinyl is fairly durable but can be more easily damaged by sharp objects or heavy impacts compared to WPC, especially in high-traffic areas.

WPC's resistance to physical damage makes it ideal for areas with heavy foot traffic or environments with pets or young children.

3. Low Maintenance

Another significant advantage of WPC flooring is its low maintenance. Unlike hardwood, which needs regular sanding, refinishing, and polishing, WPC floors require very little upkeep. Cleaning is simple, often just requiring a sweep or mop to keep the floor looking fresh. There’s no need for waxing or sealing, unlike hardwood floors, which require regular treatments to maintain their appearance.

Comparison with other flooring types:

Hardwood: Requires regular maintenance, including sanding, refinishing, and re-oiling to keep its glossy finish.

Laminate: Requires occasional cleaning, but it's prone to fading and scratching over time.

Vinyl: Vinyl is low-maintenance but can fade and lose its shine with heavy use.

WPC's wear layer also helps maintain its appearance, keeping it looking new with minimal effort.

4. Easy Installation

WPC flooring offers an easy installation process that is perfect for DIY enthusiasts and professionals alike. Most WPC flooring planks use a click-lock installation system, which allows for hassle-free setup without the need for glue, nails, or staples. This click-together design also helps eliminate issues such as warping or gapping between planks.

Comparison with other flooring types:

Hardwood: Installation of hardwood floors can be time-consuming and costly, often requiring professional help.

Laminate: While laminate also features a click-lock system, it does not offer the same level of moisture resistance and durability as WPC.

Vinyl: Vinyl is relatively easy to install, but the look and feel may not be as high-end as WPC, particularly in spaces that require a natural wood appearance.

With WPC flooring, homeowners can complete the installation process more quickly and without the need for specialized tools or professional services.

5. Aesthetic Appeal

WPC flooring is available in a wide range of designs, colors, and textures, offering aesthetic appeal that mimics the natural look of wood, stone, or tile. With advancements in printing technology, WPC floors can achieve a high level of realism, making it an excellent choice for those looking for the warmth of wood floors without the associated maintenance and upkeep.

Comparison with other flooring types:

Hardwood: While hardwood offers a timeless look, it is more expensive and may not offer the variety of designs available with WPC.

Laminate: Laminate can also mimic wood, but the texture and appearance are often less realistic than WPC flooring.

Vinyl: Vinyl can replicate wood or stone, but it generally lacks the depth and texture that WPC flooring offers.

WPC flooring allows homeowners to achieve the look of real wood or stone floors with the added benefits of easier maintenance and enhanced durability.

6. Environmentally Friendly

Many WPC flooring products are made from recycled materials, including reclaimed wood fibers and plastics, which makes it an environmentally friendly option compared to traditional hardwood floors. WPC flooring reduces the need for deforestation, and its use of recycled materials helps to reduce plastic waste, making it a more sustainable choice for eco-conscious consumers.

Comparison with other flooring types:

Hardwood: While hardwood floors come from trees, the environmental impact can be significant, especially if the wood is sourced unsustainably.

Laminate: Laminate flooring uses synthetic materials, and while it can be made from recycled content, it’s not as eco-friendly as WPC flooring.

Vinyl: Vinyl flooring is made from PVC, which is not biodegradable and has a higher environmental impact than WPC made from natural fibers and recycled plastics.

Where Can WPC Flooring Be Used?

WPC flooring is versatile and can be used in many different settings. Some of the most common places where WPC flooring is ideal include:

Residential Homes: WPC flooring is a popular choice for living rooms, dining rooms, bedrooms, kitchens, and bathrooms. Its water resistance and durability make it perfect for homes with high foot traffic and moisture-prone areas.

Commercial Spaces: Due to its resilience, WPC flooring is widely used in commercial environments such as offices, retail stores, restaurants, and hospitality settings. It can withstand the heavy traffic typical in these environments while maintaining its aesthetic appeal.

High-Moisture Areas: WPC flooring excels in areas where moisture levels are typically high, such as basements, bathrooms, and kitchens. Traditional hardwood floors may warp or buckle in these environments, but WPC floors remain intact.

Underfloor Heating Systems: WPC flooring is compatible with underfloor heating systems, making it a great option for homes or buildings with radiant heat.

WPC Flooring: 7 Types

1. Standard WPC Flooring

Standard WPC flooring is the most basic and widely used type. It features a core made of a blend of wood fibers and plastic resins, offering a strong and water-resistant foundation. The top layer is typically a high-definition print that mimics the appearance of natural wood, stone, or tile.

Features:

Water-resistant: Suitable for high-moisture areas like kitchens, bathrooms, and basements.

Scratch and dent-resistant: Designed to withstand daily wear and tear, making it ideal for high-traffic areas.

Easy to install: Most standard WPC floors come with a click-lock installation system, allowing for quick, glue-free setup.

Best for: Residential and commercial applications in areas that require water resistance and durability.

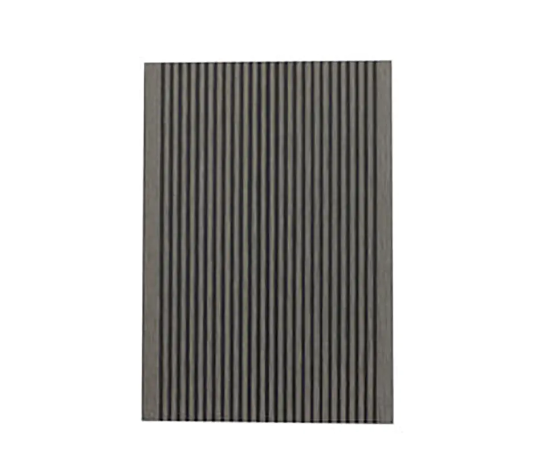

2. Embossed WPC Flooring

Embossed WPC flooring features a textured surface that mimics the natural grains of wood or the patterns of stone. The texture adds depth and realism to the flooring, making it look and feel like natural materials. This type of WPC flooring often has a raised or patterned texture that provides both aesthetic appeal and functional benefits, such as improved traction.

Features:

Realistic appearance: The textured surface mimics the feel of natural wood or stone, adding a tactile element to the design.

Slip-resistant: The embossed surface provides better traction, which is especially important in wet areas like bathrooms or kitchens.

Variety of textures: Available in a range of patterns, including wood grains, stone textures, and more.

Best for: Areas where both aesthetics and functionality are important, such as kitchens, bathrooms, and entryways.

3. Waterproof WPC Flooring

Waterproof WPC flooring is a type of WPC flooring specifically designed to offer superior protection against water. While all WPC flooring is water-resistant to some extent, waterproof WPC flooring takes this a step further with an additional layer of protection, ensuring that water cannot penetrate the surface and cause damage to the core.

Features:

Superior water protection: Ideal for rooms with high moisture levels, such as bathrooms, basements, and laundry rooms.

Fully sealed core: The core is completely sealed to prevent water absorption, unlike standard WPC that may still absorb moisture over time.

Enhanced durability: With increased resistance to water damage, this type of WPC flooring lasts longer even in areas with standing water.

Best for: High-moisture areas such as bathrooms, kitchens, laundry rooms, basements, and even outdoor spaces.

4. Hybrid WPC Flooring

Hybrid WPC flooring is a combination of WPC and other materials, often incorporating a stone plastic composite (SPC) layer beneath the WPC core. This hybrid structure offers additional strength and durability, making it ideal for environments with heavy foot traffic or where additional stability is required.

Features:

Extra stability: The combination of materials ensures that the flooring is not only durable but also more stable, even in areas with fluctuating temperatures.

Enhanced sound insulation: Hybrid WPC often comes with soundproofing features, making it quieter underfoot compared to other flooring types.

Improved resistance to impact and wear: The added strength of the hybrid structure makes it highly resistant to dents and scratches.

Best for: Commercial spaces, offices, and high-traffic residential areas that require enhanced durability and stability.

5. Hand-Scraped WPC Flooring

Hand-scraped WPC flooring is designed to mimic the rustic charm of traditional, hand-scraped wood floors. This type of WPC flooring features a distressed surface that gives it a more natural, vintage appearance, with visible texture variations and imperfections.

Features:

Vintage appeal: The hand-scraped surface offers an old-world charm, perfect for rustic or farmhouse-style interiors.

Durable finish: The surface is highly durable and resistant to daily wear, despite its distressed appearance.

Unique design: Each plank has a slightly different appearance, giving the flooring a personalized and distinctive look.

Best for: Homes or spaces that embrace rustic, vintage, or farmhouse-inspired designs.

6. Stone-Polymer Composite (SPC) WPC Flooring

SPC WPC flooring is a variation of the standard WPC floor, incorporating a stone-plastic composite layer underneath the wood-plastic core. This provides additional rigidity, impact resistance, and stability, making it perfect for spaces that need high-performance flooring.

Features:

Rigid core: The stone-polymer composite layer adds rigidity, making the flooring less prone to expansion and contraction in varying temperatures.

Increased durability: SPC WPC floors are highly resistant to heavy impacts, scratches, and stains.

More affordable: SPC WPC flooring tends to be more affordable than other WPC flooring options while still providing a premium look.

Best for: Commercial and residential applications that require extra durability and stability, such as in high-traffic areas, offices, and shops.

7. WPC Flooring with Attached Underlayment

WPC flooring with attached underlayment comes with a pre-installed padding layer that helps with sound insulation, comfort underfoot, and additional moisture protection. This is a convenient option for those who want the benefits of a padded floor without needing to install a separate underlayment.

Features:

Enhanced comfort: The attached underlayment adds comfort and cushioning, making it ideal for areas where you’ll be standing for long periods, such as kitchens or offices.

Sound insulation: The underlayment helps reduce noise transmission between floors, which is ideal for multi-story buildings or apartments.

Moisture barrier: The attached underlayment often comes with an added layer of moisture protection, which is beneficial in moisture-prone areas.

Best for: Areas that require both noise reduction and comfort, such as bedrooms, living rooms, and offices.

How to Care for WPC Flooring

One of the main advantages of WPC flooring is its low maintenance requirements. However, there are still a few steps you can take to keep it looking its best:

Sweep or Vacuum Regularly: Dust and dirt can accumulate on the floor, so it's important to sweep or vacuum regularly to prevent scratches and wear.

Clean Spills Immediately: While WPC flooring is water-resistant, it's still a good idea to wipe up any spills as soon as possible to avoid staining.

Use a Damp Mop: Occasionally, you can mop the floor with a damp mop to remove any residue or dirt. Avoid using excess water, as standing water can still damage the floor.

Place Rugs in High-Traffic Areas: To prolong the lifespan of your WPC flooring, consider using rugs or mats in areas with high foot traffic to protect the surface from damage.

Is WPC Flooring Waterproof?

WPC (Wood Plastic Composite) flooring is water-resistant, which means it can handle moisture better than traditional wood or laminate flooring. However, it’s not completely waterproof. This means it can survive spills, humidity, and occasional wetness without getting damaged, but prolonged exposure to standing water can still cause harm.

How Does WPC Flooring Handle Water?

WPC flooring is made by combining wood fibers and plastic. The plastic layer makes the flooring resistant to water. It won’t absorb moisture like wood, so it won’t swell or warp when exposed to moisture. This makes it a great choice for places like kitchens, bathrooms, and basements where water is commonly present.

What Are the Key Differences Between WPC and SPC Flooring?

When choosing the right flooring option, WPC (Wood Plastic Composite) and SPC (Stone Plastic Composite) are two popular choices that offer durability, moisture resistance, and a variety of aesthetic options. While both are engineered to provide high-performance flooring, they differ in their composition, structure, and ideal usage. Understanding these differences can help you make a more informed decision for your flooring needs.

1. Composition and Core Structure

The main difference between WPC and SPC flooring lies in their core material.

WPC Flooring: The core of WPC flooring is made from a combination of wood fibers (or sawdust) and plastic (usually PVC). This blend gives WPC flooring a lighter, more flexible feel and offers enhanced comfort underfoot, similar to traditional wood flooring.

SPC Flooring: SPC flooring, on the other hand, has a core made from a stone powder (such as limestone) and PVC. This makes the SPC core much denser, heavier, and more rigid compared to WPC. The solid core offers superior stability, making SPC less likely to expand or contract with changes in temperature and humidity.

Key takeaway: WPC is more flexible and lightweight due to its wood-plastic core, while SPC is denser and more rigid, providing extra stability.

2. Durability and Impact Resistance

The durability of both WPC and SPC flooring makes them ideal for high-traffic areas, but their performance differs in certain conditions:

WPC Flooring: WPC is highly durable and resistant to wear and tear, but it is softer compared to SPC flooring due to its wood fiber content. As a result, WPC may be more prone to denting or scratching under heavy pressure or impact.

SPC Flooring: SPC is more durable in terms of impact resistance due to its dense stone-plastic core. This makes SPC an excellent choice for commercial spaces or homes with high foot traffic or heavy furniture. SPC flooring is less likely to dent, scratch, or show signs of damage under pressure.

Key takeaway: SPC flooring offers better impact resistance and is more durable under heavy use compared to WPC flooring.

3. Water Resistance

Both WPC and SPC flooring are highly water-resistant, but they perform differently in extreme conditions:

WPC Flooring: WPC flooring is resistant to water and moisture but can still be vulnerable to prolonged exposure to standing water. Since WPC has a softer core, prolonged moisture exposure can eventually lead to swelling or damage, particularly at the edges or joints.

SPC Flooring: SPC flooring is typically more waterproof than WPC due to its stone-based core. SPC is designed to resist water even in the most challenging environments, such as basements or areas with high humidity. The rigid core is less likely to absorb water or suffer from warping, making it ideal for spaces that experience frequent exposure to moisture.

Key takeaway: SPC flooring is more waterproof and better suited for areas prone to heavy moisture exposure, such as basements, kitchens, and bathrooms.

4. Comfort and Sound Insulation

When it comes to comfort underfoot and noise reduction, WPC and SPC offer different experiences:

WPC Flooring: The wood-plastic composite structure provides a softer, more comfortable feel underfoot. WPC is generally warmer than SPC and offers better sound insulation, which can be beneficial in multi-story homes or apartments. Some WPC options even come with pre-attached underlayment, further enhancing sound absorption and comfort.

SPC Flooring: SPC, due to its dense stone core, can feel harder underfoot and may not provide as much comfort or sound insulation as WPC. However, its durability makes it ideal for spaces that require high performance, and it often requires additional underlayment for noise reduction and added comfort.

Key takeaway: WPC flooring is more comfortable and provides better sound insulation than SPC flooring, but SPC is more rigid and durable for high-traffic areas.

5. Installation Process

The installation of both WPC and SPC flooring is typically DIY-friendly and uses a click-lock system, but there are differences in terms of ease and flexibility:

WPC Flooring: WPC floors are easier to cut and install because of their softer, more flexible core. They’re also more forgiving when it comes to uneven subfloors, making installation smoother in spaces that may not have perfectly level surfaces.

SPC Flooring: SPC flooring, due to its rigid stone core, can be more difficult to cut and install, especially in tight corners or intricate layouts. However, its dense nature makes it more stable, which is advantageous for installation in spaces that require a firmer surface.

Key takeaway: WPC is easier to install and better for DIY projects, while SPC may require more effort but provides greater stability once installed.

6. Aesthetic Variety

Both WPC and SPC offer a range of styles, colors, and designs, but there are some differences in terms of how they replicate natural materials:

WPC Flooring: WPC floors tend to have a more natural wood look and feel. The printed surface layer can closely mimic the texture and appearance of real wood, making it a great choice for homeowners looking to replicate hardwood flooring without the cost or maintenance.

SPC Flooring: SPC flooring can also replicate wood and stone looks, but it is often seen as more suited to a modern, industrial style due to its rigid and durable nature. The design options may not feel as authentic or warm as WPC but still provide a stylish, high-performance option for various settings.

Key takeaway: WPC generally offers more natural wood aesthetics, while SPC provides a broader range of modern, durable finishes.

Summary of Key Differences Between WPC and SPC Flooring

| Feature | WPC Flooring | SPC Flooring |

|---|---|---|

| Core Composition | Wood fibers and plastic (PVC) | Stone powder and plastic (PVC) |

| Durability | Less impact-resistant, softer, may dent | More impact-resistant, harder, less likely to dent |

| Water Resistance | Water-resistant, but not fully waterproof | Fully waterproof, great for high-moisture areas |

| Comfort and Insulation | Softer underfoot, better sound insulation | Harder underfoot, requires extra underlayment for sound insulation |

| Installation | Easier to cut and install | More rigid, harder to cut, but more stable |

| Aesthetic Appeal | Best for natural wood looks | Best for modern, industrial styles, and durability |

WPC Flooring vs. Traditional Hardwood Flooring

1. Material Composition

WPC Flooring: WPC is made from a combination of wood fibers and plastic resins, creating a composite material. This combination makes it lightweight yet sturdy, with added benefits like moisture resistance and flexibility.

Traditional Hardwood Flooring: Traditional hardwood flooring is crafted from solid natural wood. It retains all the natural qualities of wood, including its unique grain patterns, color variations, and warmth.

Key Difference: WPC is a synthetic blend of wood and plastic, while hardwood is a completely natural material.

2. Durability and Water Resistance

WPC Flooring: WPC floors are highly durable and water-resistant, making them ideal for areas prone to moisture, such as kitchens, bathrooms, and basements. The plastic content helps protect the floor from water damage, stains, and scratches.

Traditional Hardwood Flooring: Hardwood flooring, although strong, is more vulnerable to moisture. Water can cause it to warp or swell, especially in high-humidity areas or with accidental spills. It also tends to scratch and dent more easily, particularly in high-traffic zones.

Key Difference: WPC is more resilient against water damage, while hardwood can suffer from moisture exposure and requires careful maintenance.

3. Maintenance Requirements

WPC Flooring: One of the key advantages of WPC is its low maintenance. It doesn’t require sanding, refinishing, or sealing. It only needs basic cleaning such as sweeping or mopping. Its wear layer adds extra protection against stains and scratches.

Traditional Hardwood Flooring: Hardwood requires regular maintenance, including refinishing every few years. It is more prone to damage from spills, dirt, and furniture marks. Additionally, moisture can lead to the need for refinishing more often.

Key Difference: WPC is much easier to care for with minimal upkeep, whereas hardwood needs frequent maintenance and refinishing to retain its beauty.

4. Comfort and Aesthetic Appeal

WPC Flooring: WPC flooring offers a variety of styles, from wood-look designs to stone and tile-like appearances. It is designed to mimic the natural appearance of wood but with more flexibility in terms of finishes and colors. The softer core also provides a more comfortable feel underfoot compared to hardwood.

Traditional Hardwood Flooring: Hardwood provides a classic, timeless appearance with unique grains and textures that are hard to replicate. Each plank is distinctive, and over time, hardwood can develop a rich patina that enhances its beauty. However, it can feel harder underfoot compared to WPC.

Key Difference: Hardwood offers a more authentic natural wood look, while WPC offers flexibility in design, replicating various materials and providing a softer feel.

5. Installation Process

WPC Flooring: WPC is easy to install with a click-lock system, making it ideal for DIY projects. The planks simply snap together without the need for glue or nails, which speeds up the installation process. It can be installed over most existing floors, including concrete, without the need for a subfloor.

Traditional Hardwood Flooring: Installing hardwood floors is more labor-intensive and typically requires professional installation. Hardwood must be nailed or glued to the subfloor, and the planks need to acclimate to the room before installation to prevent expansion or contraction.

Key Difference: WPC flooring is easier to install, while hardwood flooring requires more time, skill, and professional help.

6. Cost Considerations

WPC Flooring: WPC is generally more affordable than hardwood flooring. Its synthetic nature and ease of installation contribute to lower upfront costs. Moreover, since it requires less maintenance, the long-term costs are also lower.

Traditional Hardwood Flooring: Hardwood is more expensive, both in terms of material cost and installation. The higher quality and natural origin of the wood contribute to its price. Additionally, ongoing maintenance adds to the cost over time.

Key Difference: WPC is budget-friendly, while hardwood is a more expensive option, both in terms of initial cost and long-term care.

7. Environmental Impact

WPC Flooring: WPC floors can be made from recycled wood fibers and plastic materials, making them an eco-friendly option when produced responsibly. However, since they contain plastic, they are less biodegradable than natural wood.

Traditional Hardwood Flooring: Hardwood is a natural resource that, when harvested sustainably, can be a more eco-friendly option. However, concerns around deforestation can arise if the wood is not sourced responsibly.

Key Difference: Hardwood has the potential to be more environmentally friendly if sustainably sourced, but WPC can also be made from recycled materials, though it contains plastic.

Summary of Key Differences Between WPC and Traditional Hardwood Flooring

| Feature | WPC Flooring | Traditional Hardwood Flooring |

|---|---|---|

| Material Composition | Wood fibers + plastic resins | Natural wood from trees |

| Durability | Highly durable, scratch, and moisture-resistant | Can dent, scratch, and warp with moisture exposure |

| Maintenance | Low maintenance, easy to clean | Requires sanding, refinishing, and moisture protection |

| Aesthetic Appeal | Variety of designs, can mimic wood, stone, or tile | Natural wood beauty with unique grain patterns |

| Installation | Easy, click-lock system, DIY-friendly | More complex, often requires professional installation |

| Cost | More affordable and budget-friendly | Higher upfront cost, more expensive installation |

| Environmental Impact | Made from recycled materials, less sustainable than wood | Renewable resource if sourced sustainably |

WPC Flooring Installation Guide

Installing WPC (Wood Plastic Composite) flooring is a relatively simple process that can be accomplished by DIY enthusiasts or professionals alike. With the right preparation, tools, and understanding of the process, you can achieve a durable and attractive floor that enhances the look of any room. In this guide, we’ll walk you through each step of the WPC flooring installation process to ensure your project is successful.

1. Preparing the Area for Installation

Before starting the installation, it's crucial to prepare the area properly. Here's what you need to do:

Clear the Room: Remove all furniture, existing flooring (if necessary), and other obstructions. If you are replacing an old floor, make sure the surface is clean and free of debris.

Check the Subfloor: Ensure the subfloor is clean, dry, and level. WPC flooring can be installed over most existing surfaces, including concrete, wood, or tile, but the surface must be smooth. If the subfloor is uneven, it might require repair or leveling.

Acclimate the WPC Planks: Allow the WPC planks to acclimate to the room's temperature and humidity for at least 48 hours before installation. This will help prevent expansion or contraction after the installation is complete.

2. Gathering the Necessary Tools

You won't need a lot of specialized tools to install WPC flooring, but there are a few basic ones that will make the process easier:

Measuring Tape: For precise measurements of the room and the planks.

Utility Knife: For cutting the planks if needed.

Tapping Block: Helps ensure the planks fit snugly together without damaging the edges.

Pull Bar: Used to secure the last row of planks tightly in place.

Spacers: These help maintain the proper expansion gap around the edges of the room.

Rubber Mallet: For tapping the planks into place without damaging them.

Level: To make sure the subfloor is even before starting.

3. Installing the First Row of Planks

The first row of planks is crucial for a straight and even installation. Here's how to get started:

Place the Spacers: Place spacers between the wall and the first row of planks. This gap is essential for allowing the floor to expand and contract with changes in temperature and humidity.

Lay the First Plank: Start in one corner of the room and lay the first plank along the edge of the wall. Ensure that the tongue side of the plank is facing the wall, as this will connect with the next row.

Join the Planks: Continue placing the planks by clicking them together at the tongue and groove edges. WPC planks usually have a click-lock system, so you simply need to angle and press the planks together until they snap into place.

Ensure Alignment: Use the measuring tape to check that the first row is straight and aligned. A crooked first row will affect the entire floor's appearance.

4. Installing Subsequent Rows

Once the first row is in place, the next steps are similar:

Fit the Next Row: Begin the second row by inserting the tongue of the second plank into the groove of the first plank. Again, angle the planks to lock them together, and then press down to snap them into place. Use a rubber mallet to ensure a secure connection without damaging the edges.

Continue the Pattern: Work your way across the room, row by row. Stagger the seams between rows by starting each row with a plank that's a few inches shorter than the previous one. This creates a more natural look and adds stability to the floor.

Use Spacers: Maintain a consistent gap from the wall with spacers between the planks and the wall. This ensures that the floor can expand and contract properly.

5. Cutting Planks for Fit

As you approach the end of each row, you may need to cut planks to fit:

Measure and Mark: Use a measuring tape to determine how much of the plank needs to be cut. Mark the plank with a pencil.

Cut the Plank: Use a utility knife or a saw to cut the plank to the desired length. If you use a utility knife, score the plank and then snap it along the scored line. For a cleaner cut, use a saw.

Install the Cut Plank: Once the plank is cut, place it in position, making sure it fits snugly against the wall, and tap it into place with the rubber mallet.

6. Installing the Last Row

The last row is often the most challenging, as the planks will need to fit precisely to the wall:

Measure and Cut: Measure the width of the last row and cut the planks accordingly. Be sure to leave the necessary expansion gap between the planks and the wall.

Use the Pull Bar: Because the last row is often harder to fit into place, use a pull bar to tap the planks tightly into the previous row. This ensures the planks are secure and there are no gaps between them.

7. Adding Finishing Touches

Once all the planks are installed, it's time to finish the installation:

Remove the Spacers: Take out the spacers from between the planks and the wall.

Install Baseboards: To cover the expansion gap around the edges, install baseboards or quarter round molding. This not only hides the gap but also gives the floor a polished, finished look.

Clean the Floor: Sweep or mop the floor to remove any dust or debris left over from the installation. Avoid using excessive water or harsh chemicals.

8. Enjoy Your New WPC Flooring

Once the installation is complete, your new WPC flooring will be ready to use. The floor should be solid, secure, and provide years of low-maintenance durability. Enjoy your beautiful new floor that combines the look of wood with the benefits of synthetic materials!

How to Maintain WPC Flooring

1. Regular Cleaning

One of the most important aspects of maintaining your WPC flooring is regular cleaning. Cleaning helps prevent dirt, dust, and debris from accumulating, which can scratch the surface and dull the appearance over time.

Sweeping: Use a soft-bristle broom or a vacuum with a soft attachment to remove dirt, dust, and debris from the floor. Regular sweeping prevents dirt from scratching the surface of the planks.

Mopping: WPC flooring is resistant to moisture, but excessive water can damage it over time. When mopping, use a damp mop rather than soaking the floor. Avoid harsh cleaning agents, and stick to a mild cleaner that is safe for vinyl or plastic surfaces.

Spot Cleaning: For spills or stains, clean them immediately using a soft cloth and a mild cleaning solution. Wipe up spills like water, coffee, or food quickly to avoid staining.

2. Avoid Using Harsh Chemicals

While WPC flooring is resistant to water, it's important to avoid using harsh chemicals or cleaners, as these can damage the surface and finish. Strong detergents, bleach, or ammonia-based cleaners can cause discoloration or degradation of the wear layer.

Use Gentle Cleaners: Choose pH-balanced cleaners or those specifically designed for vinyl or composite materials. These cleaners will effectively clean without harming the surface.

Test New Products: Always test a small, inconspicuous area before using any new cleaning product. This helps ensure it won't cause any unwanted damage or discoloration.

3. Prevent Scratches and Dents

Although WPC flooring is durable and resistant to wear, it's still susceptible to scratches and dents, especially from heavy furniture or sharp objects.

Use Furniture Pads: Place felt pads or furniture protectors under the legs of furniture and heavy appliances to prevent scratches. These pads help distribute the weight and protect the floor from damage.

Area Rugs and Mats: In high-traffic areas or entryways, use area rugs or doormats to help catch dirt, moisture, and debris before they reach the floor. This is especially important in outdoor spaces or homes with pets.

Avoid Dragging Furniture: Never drag heavy furniture across your WPC floor. Instead, lift and move items carefully to avoid scratching the surface.

4. Control Humidity and Temperature

While WPC flooring is designed to handle moisture better than traditional wood flooring, it's still important to maintain proper humidity levels in your home or business to ensure the floor performs optimally.

Ideal Temperature and Humidity: WPC floors generally perform best in environments where the temperature remains between 60-80°F (15-27°C) and the humidity level is controlled. Extreme fluctuations in temperature and humidity can cause the floor to expand or contract, leading to gaps or warping.

Use a Humidifier or Dehumidifier: In areas where humidity levels fluctuate (such as basements or bathrooms), consider using a humidifier in winter or a dehumidifier in summer to maintain a stable environment.

5. Prevent Direct Sunlight Exposure

Although WPC flooring is designed to be UV-resistant, prolonged exposure to direct sunlight can cause the flooring's color to fade over time. This is especially true for darker colors or flooring with intricate patterns.

Use Curtains or Blinds: In areas with lots of sunlight, consider using curtains or blinds to block direct sunlight during peak hours. This helps preserve the color and integrity of the floor.

Area Rugs for Sun-Exposed Spots: In high-sun areas, use area rugs or runners to protect the flooring from UV rays.

6. Repairing Scratches and Minor Damage

If your WPC flooring does get scratched or damaged, it's relatively easy to repair minor issues without replacing the entire floor.

Buff Out Minor Scratches: For small surface scratches, you can use a soft cloth and mild abrasive cleaner to gently buff out the marks. Always rub in the direction of the grain to avoid further damage.

Patch Repairs: For deeper scratches or dents, you can purchase a repair kit designed for WPC flooring. These kits usually contain fillers that can be applied to the damaged area, followed by buffing for a smooth finish.

7. Periodic Deep Cleaning

While regular cleaning is essential, it's also good practice to perform a deeper clean every few months to keep your WPC flooring looking its best.

Use a Steam Mop (Optional): Some WPC floors are safe to clean with a steam mop. If you choose to use one, ensure that your flooring is compatible and follow the manufacturer’s guidelines.

Remove Grime: Over time, grime and dirt can accumulate in the grooves or edges of the planks. Use a soft brush or microfiber cloth to gently clean these areas.

8. Prevent Heavy Impact

Even though WPC flooring is resilient, heavy impacts from dropping hard objects can still cause damage.

Be Mindful of Heavy Items: When moving large or heavy items, lift them instead of dragging them across the floor. This will reduce the chances of denting or scratching the planks.

Use Protective Coatings: If necessary, consider applying a protective floor coating specifically designed for WPC flooring. This can add an extra layer of protection against scratches and stains.

Maintaining WPC flooring is straightforward and requires minimal effort, but following these simple care tips will ensure that your floor remains durable, attractive, and long-lasting. Regular cleaning, proper protection, and controlling environmental factors can help prevent damage and preserve the beauty of your WPC flooring for years to come.

For high-quality WPC flooring solutions and expert advice on care and maintenance, visit our website at pvcfloortile.com or reach out to us at Zhejiang Ousikai New Material Co., Ltd for more information and to explore our full range of products. We are committed to providing durable, high-performance flooring solutions that fit your needs and style.

English

English 中文简体

中文简体 Español

Español