What is LVT Flooring?

If you've been looking for new flooring options, you may have heard of China LVT Flooring. These luxury vinyl tiles have become a popular choice for both residential and commercial spaces. Their appeal lies in the nice combination of modern style and everyday practicality. They may look similar to wood, stone, or ceramic, but they're lighter, easier to install, and often more affordable. For buyers and project managers, understanding the true properties of LVT flooring can greatly facilitate the selection process. It's more than just a product name; it's a material with special qualities that significantly improve its long-term use and maintenance.

Difference between LVT and regular PVC flooring

At first glance, LVT and regular PVC flooring may seem similar, since both are made from vinyl materials. But the difference lies in how they are designed and used. Traditional PVC flooring is usually a single, flexible sheet. It is practical, affordable, and often found in schools, factories, or spaces that need quick and simple coverage.

LVT, on the other hand, is built with more layers and designed to imitate natural surfaces like wood or stone. Each tile or plank is thicker than a standard PVC sheet, which makes it more stable underfoot. The surface layer of LVT is also treated with protective coatings, so it can handle scratches, stains, and daily wear more effectively.

For buyers, the key takeaway is this: PVC flooring is often chosen for basic functionality, while LVT is selected when appearance and durability also matter. This makes LVT a practical choice for offices, retail shops, and residential interiors where design and comfort are important alongside cost control.

What Materials Make Up LVT Flooring?

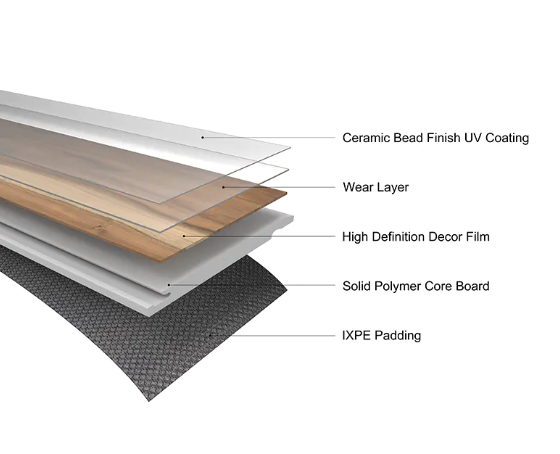

After looking at how LVT differs from standard PVC flooring, it’s helpful to understand what exactly goes into each tile or plank. Unlike a simple vinyl sheet, LVT is a layered product. Every layer has its own role in creating the balance of design, durability, and comfort.

Wear Layer – This is the transparent top coating. It protects the surface from scratches, stains, and general wear. The thickness of this layer often determines how well the flooring holds up in heavy-use areas.

Design Layer – Just below the wear layer is the printed film. This is where the realistic look of wood, stone, or ceramic comes from. Advances in printing technology make these patterns highly detailed, which gives LVT its natural appearance.

Core Layer – This middle section provides stability and strength. It is usually made from vinyl and sometimes combined with additional reinforcement materials. The thickness of the core also affects how solid the floor feels underfoot.

Backing Layer – At the bottom, the backing layer supports the structure and helps the flooring stay balanced on the subfloor. In some products, this layer includes sound reduction or moisture resistance features.

By combining these layers, LVT becomes more than just vinyl—it turns into a flooring solution that feels stable, looks appealing, and performs well in daily use.

Is LVT Flooring Waterproof?

One of the practical questions buyers often ask is whether LVT Flooring can handle water exposure. The answer is yes—LVT is designed to be highly resistant to moisture. Because it is made from vinyl materials, water does not easily penetrate the surface or core. This makes it a strong choice for areas where spills, humidity, or regular cleaning with water are common.

That said, it is important to note the difference between water-resistant and waterproof in real-world use. LVT tiles and planks themselves are waterproof, but the way they are installed can affect overall performance. For example, if water seeps through the seams and is left standing, it may impact the subfloor beneath. Proper installation and sealing are key to ensuring long-term protection.

For procurement managers, this feature makes LVT Flooring suitable not only for living rooms or offices, but also for kitchens, bathrooms, and retail spaces where durability against moisture is critical. By choosing the right product and paying attention to installation details, buyers can get a surface that stands up well to both daily traffic and unexpected spills.

What Looks Can LVT Flooring Imitate?

One of the main reasons LVT Flooring has become so popular is its ability to replicate the look of natural materials without the same cost or maintenance challenges. Thanks to advanced printing and embossing technology, the surface can be made to resemble a wide range of finishes. This gives buyers the freedom to choose a style that matches the space without worrying about the limits of the original material.

Here are some common appearances LVT can imitate:

| Material Look | Key Features | Typical Use Cases |

|---|---|---|

| Wood | Realistic grains, warm tones | Living rooms, bedrooms, offices |

| Stone | Natural textures, cool shades | Bathrooms, kitchens, retail shops |

| Ceramic/Tile | Clean lines, glossy or matte finish | Kitchens, hallways, commercial spaces |

| Concrete | Modern, industrial style | Cafés, showrooms, loft apartments |

| Marble | Elegant veining, high-end feel | Hotels, lobbies, luxury retail |

Because of this versatility, LVT gives procurement professionals the flexibility to meet both design goals and budget requirements in a wide range of projects.

What Are the Installation Methods?

Understanding the different installation options is important when planning a project with LVT Flooring. The method you choose can affect both the cost and the time required, as well as the long-term performance of the floor. Here are the main approaches:

Click-Lock (Floating) Installation

Each plank or tile has interlocking edges that snap together.

No adhesive is needed, making it easier and faster to install.

Ideal for projects where a temporary or easily replaceable floor is desired.

Glue-Down Installation

Adhesive is applied to the subfloor, and the LVT is pressed down.

Provides a very stable and permanent surface.

Suitable for high-traffic areas, commercial spaces, and places where extra stability is important.

Loose Lay Installation

LVT planks or tiles are simply laid down without glue or locks, relying on weight and friction to stay in place.

Installation is quick and can be reversed if needed.

Works well for large commercial spaces or areas where minimal downtime is required.

Each method has its own advantages depending on the project size, subfloor condition, and maintenance needs. For procurement managers, knowing these options helps in planning both logistics and budget, ensuring the flooring solution fits the space as intended.

Installing LVT Flooring with Underfloor Heating

Now that you know the main installation methods (click, glue-down, and lay-flat), you might be interested in learning how LVT floors work with underfloor heating. Installing LVT floors over heated surfaces involves more than just laying the tiles; it's critical to ensure their long-term performance and comfort. The installation method chosen affects how efficiently heat is transferred to the floor and the long-term stability of the floor or tiles.

Can LVT floors be installed over underfloor heating?

The answer is yes. Most modern LVT products are compatible with underfloor heating, but there are some considerations. First, the surface temperature should generally be kept below 27–28°C (approximately 80–82°F) to prevent warping or damage. Second, both the subfloor and the underfloor heating system must be properly prepared and tested before installation to ensure even heat distribution.

Click-to-fit LVT flooring is ideal for use over underfloor heating, allowing for slight expansion and contraction with temperature fluctuations. Glue-down LVT flooring offers reliable performance, but installers must select a heat-resistant adhesive. Self-installed LVT flooring is sometimes used for temporary or flexible installations, but may require special care to prevent shifting in hot conditions.

For buyers and project managers, knowing that LVT flooring can coexist with underfloor heating expands design possibilities. Offices, apartments, or showrooms can enjoy a warm and comfortable surface without compromising the aesthetics or durability of LVT flooring.

Does Installing LVT Require Professional Tools and Workers?

For anyone considering LVT Flooring, a common question is whether professional installation is necessary. The answer depends on the chosen installation method and the project’s scale.

For click-lock or loose lay LVT, basic tools such as a utility knife, tape measure, and spacers are usually sufficient. Homeowners or on-site maintenance teams can often handle the installation themselves if the space is straightforward. Glue-down installation, however, tends to be more demanding. It requires proper adhesive, rollers, and sometimes specialized cutting tools to ensure a flat and secure surface.

Even with DIY-friendly options, many companies and project managers prefer to rely on experienced personnel. Skilled installers can handle tricky layouts, irregular room shapes, and ensure the flooring meets both aesthetic and performance standards. Working with a reputable LVT Flooring Factory can provide not only high-quality materials but also guidance or professional installation services, which helps reduce the risk of mistakes and ensures the floor performs as expected over time.

For buyers, understanding the balance between DIY potential and professional support can save time, money, and effort in the long run.

Can Be Combined With Other Materials?

Many buyers and designers want to know if LVT Flooring can be used alongside other flooring types, such as wood or ceramic tiles. The answer is yes—but it requires some planning to ensure a smooth transition and consistent look. Here are some practical points to consider:

Transition Strips or Thresholds – Use transition pieces between LVT and other materials to prevent gaps, uneven surfaces, and potential tripping hazards.

Height Matching – LVT is typically thinner than hardwood or tile, so adjustments may be needed to align the floor levels.

Expansion Gaps – Leave small gaps at the edges to allow for natural expansion and contraction of different materials.

Pattern and Color Coordination – Consider the design flow; LVT can imitate wood or stone, making it easier to blend with surrounding materials.

Professional Installation Advice – When combining materials in larger spaces, consulting installers or your LVT Flooring Manufacturer can ensure proper techniques and long-term stability.

Combining LVT with other materials allows for creative design possibilities while maintaining practical performance. With careful planning, the floor can have a cohesive and functional look that meets both aesthetic and operational needs.

Does LVT Flooring Offer Sound Insulation?

Noise can be a significant concern in both residential and commercial spaces. One of the advantages of LVT Flooring is its ability to reduce sound compared with harder surfaces like ceramic tile or natural stone.

The structure of LVT—its multiple layers including the core and backing—absorbs impact noise and footstep sounds to a certain degree. Some LVT products come with additional acoustic backing, which can further enhance the quietness underfoot. This makes it suitable for offices, apartments, and retail spaces where minimizing noise is important.

While LVT won’t completely eliminate all sound, it provides a noticeable improvement over traditional hard flooring options. For procurement managers, this means choosing LVT can contribute to a more comfortable and professional environment without the need for extra soundproofing measures.

How Does LVT Feel Underfoot?

After considering LVT’s sound-absorbing qualities, it’s natural to ask how it actually feels when you walk on it. Compared with harder surfaces like ceramic tiles, LVT often provides a softer and warmer experience. The multi-layer construction, especially the core and backing layers, gives a slight cushioning effect that many people find comfortable for daily use.

Here’s a simple comparison between LVT and ceramic tile to illustrate the differences in comfort and feel:

| Feature | LVT Flooring | Ceramic Tile |

|---|---|---|

| Surface Hardness | Slightly soft, gentle underfoot | Very hard, firm |

| Warmth | Retains room temperature, feels warmer | Feels cold, especially in winter |

| Cushioning | Provides a small cushioning effect | No cushioning, hard impact |

| Fatigue | Less tiring to stand or walk for long periods | Can cause more fatigue when standing long |

| Footstep Noise | Reduced impact noise | Louder footstep sounds |

For buyers and project managers, this comparison highlights why LVT is often preferred in spaces where comfort matters, such as offices, retail stores, and residential areas. It balances durability with a more inviting underfoot experience, without losing the aesthetic appeal of wood, stone, or tile patterns.

Is LVT Flooring Prone to Scratches?

After considering how LVT feels underfoot, another practical question arises: how well does it handle scratches and everyday wear? While no flooring is completely immune, LVT is designed with a wear layer that protects against scratches, scuffs, and minor impacts.

The thickness and quality of this top layer largely determine how resistant the floor is. Areas with heavy furniture, high foot traffic, or pets may require LVT with a thicker wear layer to maintain appearance over time. In addition, protective pads under furniture and regular cleaning without abrasive tools can further reduce the risk of scratches.

For procurement managers, this means that choosing the right LVT product involves looking at both the wear layer specifications and the intended usage of the space. With proper selection and care, LVT can maintain its surface appearance for many years, combining practical durability with the design versatility that makes it attractive in the first place.

Does LVT Flooring Expand or Contract in Extreme Temperatures?

After discussing scratch resistance, another practical consideration is how LVT Flooring reacts to changes in temperature. Like most vinyl-based products, LVT can experience slight expansion or contraction when exposed to high or low temperatures. This is a normal behavior of the material and does not indicate a defect. Understanding this property is essential for ensuring long-term performance.

The degree of expansion or contraction depends on several factors. The thickness of the flooring plays a role: thicker planks or tiles are generally more stable than thinner ones. The installation method also matters. Click-lock and loose lay LVT are designed with slight movement in mind, allowing the floor to adjust naturally as temperatures fluctuate. Glue-down installations tend to be more rigid, so proper adhesive selection and allowance for expansion gaps are crucial to avoid buckling or uneven surfaces.

Indoor environment control is another key factor. Maintaining a consistent room temperature and humidity level reduces the risk of excessive movement. Extreme heat, such as from direct sunlight through large windows, or very cold conditions in unheated areas, can increase expansion and contraction, but these effects are usually minor if standard installation practices are followed.

For buyers and project managers, the practical takeaway is clear: LVT can be used in a variety of indoor environments, including offices, apartments, and retail spaces, without concern for major warping. Planning for minor expansion gaps along walls or at transitions, monitoring indoor temperatures, and following the manufacturer’s installation guidelines all help maintain the floor’s appearance and functionality over time. With these considerations, LVT offers a durable, attractive, and reliable solution for projects where both aesthetics and long-term performance are important.

How to Maintain and Clean?

Once LVT Flooring is installed, proper maintenance is key to keeping it looking fresh and extending its lifespan. The good news is that LVT is low-maintenance compared with many other flooring types. Here are some practical tips for daily care:

Regular Sweeping or Vacuuming – Dust, dirt, and small debris can cause scratches over time. Use a soft broom or vacuum suitable for hard floors to remove particles.

Damp Mopping – A slightly damp mop with a mild, pH-neutral cleaner is effective for removing dirt and stains. Avoid soaking the floor with water.

Spot Cleaning – For spills, wipe them up immediately to prevent staining or residue buildup.

Protective Pads – Place felt pads under furniture legs to reduce the risk of scratches when moving items.

Avoid Harsh Chemicals – Strong solvents or abrasive cleaners can damage the wear layer and reduce the floor’s durability.

Rugs and Mats – Use entrance mats to minimize dirt and grit brought in from outdoors, especially in high-traffic areas.

By following these simple steps, LVT Flooring can maintain its appearance and performance over time. For procurement managers, knowing that the floor is easy to clean and maintain adds confidence when specifying LVT for offices, retail spaces, or residential projects. With minimal effort, it combines practicality with the aesthetic benefits that make it a preferred choice in modern flooring solutions.

Can a Single LVT Tile Be Replaced if Damaged?

Even with careful use, accidents can happen, and individual LVT tiles or planks may get scratched, chipped, or otherwise damaged. The good news is that, in most cases, a single piece can be replaced without having to remove the entire floor.

The ease of replacement depends on the installation method. Click-lock and loose lay LVT are generally easier to replace because the planks can be unlocked or lifted individually. Glue-down tiles can also be replaced, but this may require carefully removing the adhesive and installing a new tile with fresh glue to ensure stability.

Working with a reliable LVT Flooring Supplier is especially helpful in these situations. They can provide replacement pieces that match the original design, thickness, and finish, which is crucial for maintaining a consistent look across the floor. Additionally, some suppliers offer guidance or installation support to make the replacement process smoother and minimize downtime.

For procurement managers, knowing that damaged sections can be replaced individually adds flexibility and reduces long-term maintenance costs. It also highlights the practical advantage of LVT compared with other flooring materials, where repairs might require much larger-scale interventions.

Bringing It All Together

From understanding what LVT Flooring is, to exploring its materials, installation methods, and practical features like water resistance, sound absorption, and ease of maintenance, it’s clear why this flooring option has become a versatile choice for many spaces. Whether it’s replicating the look of wood, stone, or tile, or offering comfort underfoot and long-term durability, LVT balances aesthetics with practicality in a way that meets modern project requirements.

For procurement managers and buyers, partnering with a trusted pvcfloortile factory ensures access to quality materials, guidance on installation options, and support for long-term maintenance needs. By choosing the right LVT products, you can create spaces that are visually appealing, functional, and cost-effective—all while simplifying ongoing care and potential repairs.

With careful selection, proper installation, and regular maintenance, LVT Flooring can deliver a durable, attractive, and practical surface for offices, retail spaces, and residential projects alike, making it a smart choice for both designers and buyers looking for a reliable flooring solution.

English

English 中文简体

中文简体 Español

Español