Guide to SPC Flooring - Ousikai pvcfloortile

In recent years, SPC flooring has emerged as a nice solution in both residential and commercial flooring markets. SPC flooring is a type of rigid core flooring made from a stone-plastic composite, offering a durable and water-resistant alternative to traditional vinyl and hardwood.Known for its durability, waterproof nature, and ease of installation, SPC flooring—short for Stone Plastic Composite flooring—offers a range of technical and aesthetic benefits that set it apart from traditional vinyl and laminate flooring options.

This guide delves into the core features of SPC flooring, its applications, and what to consider when sourcing from a reliable SPC Flooring Factory.

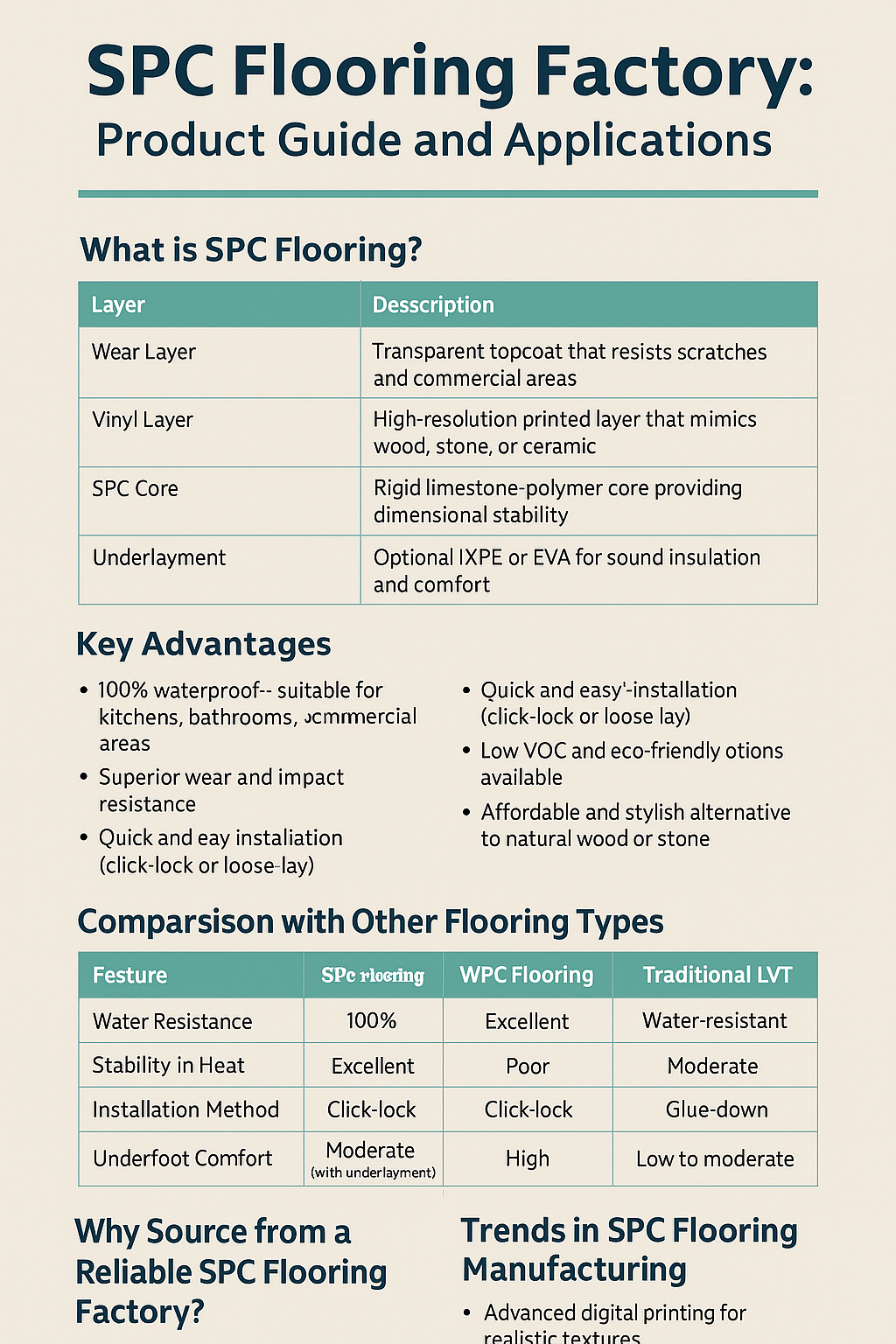

1. What is SPC Flooring?

SPC flooring is a type of rigid core vinyl flooring engineered from a combination of natural limestone powder, polyvinyl chloride, and stabilizers. The result is a strong, dimensionally stable, and waterproof flooring solution.

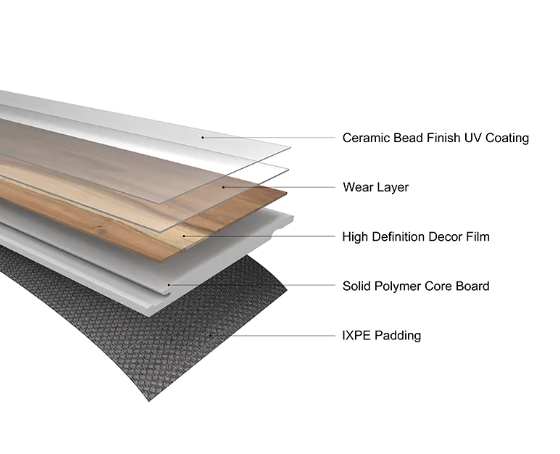

Structure Overview:

| Layer Name | Description |

|---|---|

| Wear Layer | A transparent, scratch-resistant coating that protects against daily wear. |

| Vinyl Layer | Printed with high-resolution textures to mimic wood, stone, or ceramic. |

| SPC Core Layer | Rigid composite core that offers stability, impact resistance, and waterproofing. |

| Underlayment | Optional IXPE or EVA foam backing for sound insulation and comfort. |

This multi-layered construction makes SPC flooring particularly suited for high-traffic and moisture-prone environments.

2. Why Choose SPC Flooring?

SPC flooring delivers a variety of benefits that are attractive to architects, designers, contractors, and property developers:

Waterproof: Ideal for kitchens, bathrooms, basements, and commercial spaces.

Durability: The stone composite core resists dents, impacts, and daily wear.

Dimensional Stability: SPC handles temperature fluctuations better than WPC or standard LVT.

Quick Installation: Most SPC floors use a click-lock system requiring no glue or nails.

Eco-friendly Options: Many factories offer phthalate-free, low-VOC materials.

Cost-Effective: Compared to hardwood or ceramic tile, SPC provides similar aesthetics with lower costs.

3. Application Areas

Thanks to its versatile properties, SPC flooring is widely used in both residential and commercial sectors. Common applications include:

Retail Environments: Durable enough for heavy foot traffic and easy to clean.

Hospitality Industry: Stylish and practical for hotel rooms and lobbies.

Office Spaces: Offers acoustic underlayment options for quiet environments.

Multi-Family Housing: Affordable, attractive, and long-lasting—perfect for rentals.

Healthcare Facilities: Moisture-resistant and hygienic surface suitable for clinics and senior living.

4. SPC vs Other Flooring Types

| Feature | SPC Flooring | WPC Flooring | Laminate | Traditional LVT |

|---|---|---|---|---|

| Waterproof | Yes | Water-resistant | Not waterproof | Water-resistant |

| Core Material | Stone Composite | Wood Composite | HDF | Flexible Vinyl |

| Temperature Resistance | Excellent | Good | Poor | Moderate |

| Installation Method | Click-lock | Click-lock | Click-lock | Glue-down |

| Soundproofing Options | IXPE/EVA backing | Cork/EVA | Foam underlay | Optional backing |

This comparison further highlights why professionals often prefer sourcing from a capable SPC Flooring Manufacturer when durability and performance are essential.

5. Sourcing from an SPC Flooring Factory

Choosing the right SPC Flooring Factory can significantly influence the success of a project, especially for B2B buyers. Here's what to look for:

Production Capacity: Can the factory handle large volume orders with consistent quality?

Product Certification: Are products certified to meet regional regulations (CE, Floorscore, ISO, etc.)?

Customization Options: Does the factory offer different wear layers, surface finishes (embossed, EIR, hand-scraped), and color ranges?

OEM/ODM Services: Do they support private labeling, packaging design, and custom branding?

Lead Time and Logistics: Efficient delivery timelines and export experience matter for global buyers.

A professional SPC Flooring Manufacturer should offer not only products but also technical support, market insights, and after-sales service—especially when serving long-term commercial partnerships.

6. Emerging Trends in SPC Flooring

The SPC market continues to evolve, with factories investing in advanced printing technologies, ultra-matte finishes, and antimicrobial coatings. Some current innovations include:

Clickless SPC for ultra-fast installations

Hybrid SPC-WPC products for optimized performance

SPC with real stone powder topping for luxury finishes

Biodegradable underlayment materials

These trends show how SPC Flooring Manufacturers are innovating to meet environmental standards and user expectations.

SPC flooring redefines what commercial and residential buyers expect from vinyl flooring. With its stability, waterproof design, and rich design possibilities, SPC flooring is an ideal solution for modern industrial spaces. Whether you are a builder, dealer, or interior designer, working with a trusted SPC flooring manufacturer ensures quality, durability, and long-term performance.

To learn more or request samples, visit: https://www.pvcfloortile.com/

English

English 中文简体

中文简体 Español

Español